Henninger Centre Grinding Machines: perfect for any situation

from standard to fully automated

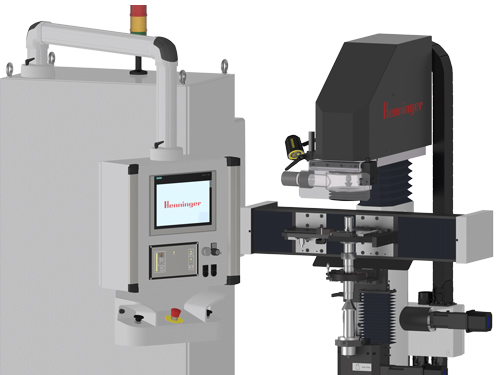

The Henninger centre grinding machines are characterised by high precision made in Germany, excellent roundness, improved runout and long durability in the machining of workpieces.

The machines are designed and manufactured in our headquarters in Straubenhardt, Germany. They are engineered for the durable application in high quality productions. Our centre grinding machines offer our customers an important way to achieve required qualitative results and increase the profitability.

We offer standard models for manual and automated situations. Our centre grinders can be adapted to the respective customer requirements with options and special solution adaptions. Our centre grinding machine series are divided according to workpiece weights, as well as horizontal and vertical alignment during machining.

Henninger Centre Grinding Machines

Overview of the ZS series: standard models & automated solutions

The Henninger centre grinding machines are characterised by high precision made in Germany, excellent roundness, improved runout and long durability in the machining of workpieces.

The machines are designed and manufactured in our headquarters in Straubenhardt, Germany. They are engineered for the durable application in high quality productions. Our centre grinding machines offer our customers an important way to achieve required qualitative results and increase the profitability.

We offer standard models for manual and automated situations. Our centre grinders can be adapted to the respective customer requirements with options and special solution adaptions. Our centre grinding machine series are divided according to workpiece weights, as well as horizontal and vertical alignment during machining.

Centre grinding machines for vertical workpieces

ZS ONE

For workpieces up to: 5 kg | 250 mm | 10 mm centre Ø

The ZS ONE is especially suitable for processing small workpieces. Easy and quick loading characterises this compact machine. Its size makes it ideal for mobile use. It can also be used as a table machine. It is mostly used for manual processing, but there is also the possibility of automation.

ZS 100 series

For workpieces up to: 100 kg | 1160 mm | 58 mm centre Ø

The ZS 100 series centre grinding machines have the highest spindle speed. This makes it possible to grind very small and filigree centres. The machine is available in 2 heights: 600 and 1.200 mm.

ZS 200 series

For workpieces up to: 500 kg | 2115 mm | 125 mm centre Ø

The ZS 200 series is especially suitable for automated production, as almost all functions can be automated.

There are three different heights for this model in the standard range. The special clamping range extends up to workpieces with a diameter of 225 mm.

ZS 1000 series

For workpieces up to: 1000 kg | 3086 mm | 188 mm centre Ø

The ZS 1000 series can process workpieces weighing up to 1.000 kg. The vice and grinding spindle can be moved vertically on this model. Runout measurement and correction between centres on the machine are possible.

Centre Grinding Machines

for vertical workpieces

ZS ONE

For workpieces up to: 5 kg | 250 mm | 10 mm centre Ø

The ZS ONE is especially suitable for processing small workpieces. Easy and quick loading characterises this compact machine. Its size makes it ideal for mobile use. It can also be used as a table machine. It is mostly used for manual processing, but there is also the possibility of automation.

ZS 100 series

For workpieces up to: 100 kg | 1160 mm | 58 mm centre Ø

The ZS 100 series centre grinding machines have the highest spindle speed. This makes it possible to grind very small and filigree centres. The machine is available in 2 heights: 600 and 1.200 mm.

ZS 200 series

For workpieces up to: 500 kg | 2115 mm | 125 mm centre Ø

The ZS 200 series is especially suitable for automated production, as almost all functions can be automated.

There are three different heights for this model in the standard range. The special clamping range extends up to workpieces with a diameter of 225 mm.

ZS 1000 series

For workpieces up to: 1000 kg | 3086 mm | 188 mm centre Ø

The ZS 1000 series can process workpieces weighing up to 1.000 kg. The vice and grinding spindle can be moved vertically on this model. Runout measurement and correction between centres on the machine are possible.

Centre grinding machines for horizontal workpieces

ZS 2000 series

For workpieces of individual size or weight | 188 mm centre Ø

Workpieces are adjusted according to the customer’s specifications with the centre grinding machine ZS 2000 series. This centre grinding machines are suitable for very heavy (up to over 1 t) or large (up to over 2 m) workpieces, and can grind centre holes simultaneously and on both sides if required. Further options and individual customisations are available.

ZS 250 series

Length & weight of the workpieces depend on the substructure | max. 148 mm centre Ø

This centre grinder is designed for the use on a machine bed or lathe.

Three adjustable axes make it possible to redefine the centre. Length and diameter of the workpieces depend on the respective substructure.

Centre grinders

for horizontal workpieces

ZS 2000 series

For workpieces of individual size or weight | 188 mm centre Ø

Workpieces are adjusted according to the customer’s specifications with the centre grinding machine ZS 2000 series. This centre grinding machines are suitable for very heavy (up to over 1 t) or large (up to over 2 m) workpieces, and can grind centre holes simultaneously and on both sides if required. Further options and individual customisations are available.

ZS 250 series

Length & weight of the workpieces depend on the substructure | max. 148 mm centre Ø

This centre grinder is designed for the use on a machine bed or lathe.

Three adjustable axes make it possible to redefine the centre. Length and diameter of the workpieces depend on the respective substructure.

Custom solutions for special workpieces

We offer special solutions and customised designs for all machines. Our team of experts will be happy to advise you, in person, by phone, or in an online meeting with shared screens. Contact us.

Which centre grinding machine increases your profitability?

Contact us directlyGo to the centre grinding configuratorWhat exactly is centre grinding?

The Henninger Centre Grinding TechnologyThe difference in the centre grinding process with a fixed or rotating workpiece

Machining with the fixed workpiece is recommended for unprocessed blanks, pre-turned parts and in large series.

This process is extremely easy to automate and integrate into a cell or production line. By moving the axis, the position of the centre can be changed when the workpiece is standing.

The advantage with a rotating workpiece is that the axis can be fetched to a specific position of the workpiece. This is beneficial if the position of the centring hole has to run to a bearing seat or to the teeth of a gear shaft.

For this, a good roundness is required at the clamping diameter, as the roundness is reproduced in the centre. This method can also be used for repairing workpieces when the centre hole must run to a finished diameter.

All benefits of the Henninger Centre Grinding Technology at a glance:

safety

higher process stablility

perfection

defined position for all final operations

precision

highest accuracy for your workpiece

roundess record:

roundness in the centre 1µm or less

reduction

lowering the reject rate

accuracy

less grinding allowance

Our product rangeincludes a wide variety of centre grinding machines in different sizes and variants. Our ZS series also include special solution machines for all requirements and wishes. Every type has different possibilities for options, automation and customization.

We are happy to offer youtest machinings with your workpieces. You can also rely on our contract manufacturing service.