Technical Data of the Henninger Centre Grinding Machine ZS ONE

Workpiece: centre diameter

Ø 1-10 mm

Machine: clamping diameter

max. 40 mm

Workpiece: length

max. 250 mm

Machine: speed

50.000 min-1

Workpiece: weight

max. 5 kg

Customisation

Options & custom solutions upon request

What is the benefit of centre grinding?

What can the ZS ONE offer besides high roundness?

As with any other Henninger centre grinder, centre grinding with the ZS ONE bringshigh precision to the entire manufacturing process. The centring hole is being perfected so that roundness of up to 1 µm can be achieved. Hence the ZS ONE centre grinding machine for a high roundness of small workpieces offers just as much precision as its bigger siblings.

Grind the outer contours of your workpieces after centre grinding as precisely as never before!

The ZS ONE impresses not only with its high quality and precision, but also with its very simple way of operation. When developing the ZS ONE, it was important to us that workpieces could be machined quickly and easily.

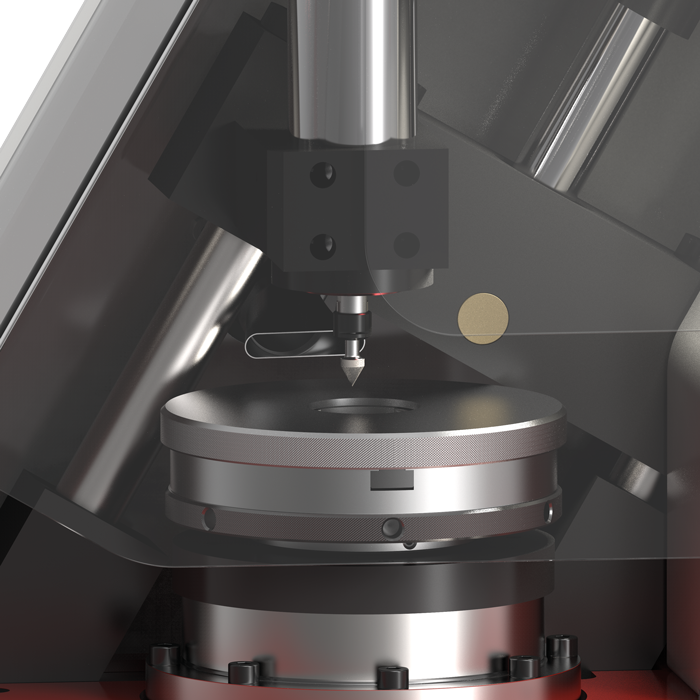

How does the centre grinder ZS ONE work?

The ZS ONE is used to rework centring holes after the hardening process. The workpiece is clamped in a precision bearing-mounted chuck. The rotary grinding process begins.

The centre is thus being put in line with the axis of rotation. After machining, the roundness in the centre corresponds to the roundness of the rotary axis, i.e. the runout of the chuck bearing: approx. 1 µm.

The tool is outside the axis of rotation. The feed movement is at a 60° angle to the axis of rotation. This causes the mounted point to move into the workpiece exactly normal to the lateral surface of the centre.

The spindle can be moved axially to adjust the projection length.

More videos about centre grinding and Henninger precision products can be found here on our Youtube channel.

For which applications are centre grinding machines used by our customers?

Typical workpieces for the ZS ONE are shafts, sleeves, bushings, spindles, small gears, screw drives, hydraulic parts, etc. where high accuracy is required.

Centre grinding with the compact ZS ONE is particularly recommended for the production of cutting tools. This includes reamers, taps, PCD tools, roller burnishing tools, smoothing tools, milling cutters, countersinks, honing tools and many other tools.

We offer ZS ONE test machining for your workpieces

Are you not sure whether centre grinding is profitable for your workpieces? Are you curious about the extent to which the Henninger precision technology increases the quality and efficiency of your production?

Visit us on site in our test centre to present the ZS ONE to you. We will be happy to discuss your complete range of parts and demonstrate centre grinding on your workpieces.

Alternatively, you can also send us your workpiece. We will be happy to carry out a test machining of the centre grinding on our demonstration model. You can be connected live to observethe grinding process in our test centre. Afterwards, we will send your workpiece back to you for inspection.

Do you want a Henninger ZS ONE centre grinding machine as a leasing option or hire purchase? We offer flexible financing options.

You are not sure whether you want to use this machine long-term? How about a 1-year leasing option or a hire purchase, for example? We offer flexible purchase options depending on your needs. Whether standard model or custom-made: all our machines are developed and manufactured by us in Germany.

Direct purchase

We deliver the ZS ONE standard model to your production!

Special solutions

Do you have specific manufacturing or option requests?

Leasing

We offer various leasing offers.

Hire purchase

Our machines can also be purchased on a hire-purchase basis.