Henninger angle head series for milling machines, boring mills and lathes

Discover our angle head series & angle head special solutions:

- for the reduction of set-up times

- for machining workpiece areas that are difficult to access

- to minimise the workpiece stresses

- for cost savings through complete machining

- to reduce machine downtimes

Innovations Made in Germany: Development, Design & Manufacturing

Our engineering team is constantly perfecting the Henninger angle head series. The Henninger angle head’s quality is characterized by high rigidity, high torques and power, reliability and a long service life. We always strive towards innovation and modern techniques.

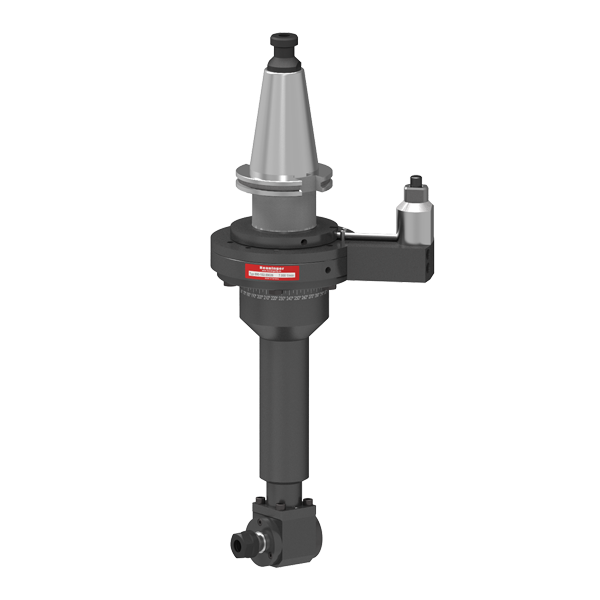

The Henninger milling heads offer the highest precision in the machining of workpieces with narrow space conditions. Our milling heads are ideally suited for inserting keyways, profiles and small internal bores in workpieces with small bore diameters. With the milling heads uneconomical shaping, broaching and grinding work can potentially be saved. We offer the appropriate milling tools for the different types of work. Our milling heads are characterised by:

- different projection lengths of the cutter arm

- the milling of complex internal contours

- drive via gear wheels

- output collets or Henninger special tapers for various milling cutters

- automatically interchangeable

- interchangeable shaft system (modular)

- vertical & horizontal versions

- high speeds up to 15.000 min-1

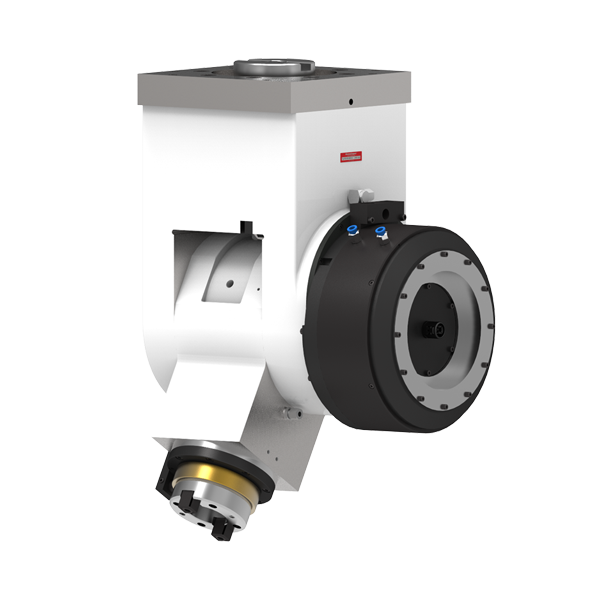

The Henninger angle heads in 90° fixed versions were developed to perform the finest and most delicate machining up to the heaviest machining on workpieces. Our angle heads offer:

- high rigidity

- high torques up to 665 Nm

- high power up to 84 kW

- high speed up to 20.000 min-1

- various length versions

- special solutions for every situation

- crown or bevel gear design

More information about the Henninger angle heads 90° static here.

The adjustable angle heads by Henninger are characterised by high precision and models designed and manufactured in Germany. These offer, among other things:

- ± 92° steplessly adjustable

- high rigidity

- output SK 50

- high torque up to 500 Nm

- high power 55 kW

Angle Heads Custom Solutions

With the custom solutions for angle heads, Henninger supplies renowned machine manufacturers worldwide who appreciate the reliability and good service of Henninger products. Requirements of our customers, which are implemented by us through special solutions are e.g. hirth toothing, motor drive, various tool clamping systems or housing shapes.

- automatic C-axis

- automatic tool changing

- hirth toothing

- extension output and drive housing

precision & many years of experience for angle heads & special solutions

The Henninger angle heads can be used universally and reduce set-up and machining times. They can be changed manually or automatically.

Torque supports with three-point support provide a more rigid connection between the angle head and the machine.

Angle heads are particularly in need when axes are missing or when the plane to be machined cannot be reached despite the presence of axes.

Henninger angle head series are used for milling, drilling, reaming and thread cutting. Our team can respond directly to customer wishes with special designs. Henninger offers years of experience and a large repertoire of application-specific special designs.

Machining of workpiece areas that are difficult to access

Difficult and hard-to-reach inner and outer contours can be machined with the angle heads. Multiple clamping of the workpieces and the resulting inaccuracies and time losses are avoided by using the Henninger angle heads.

Angle heads for various applications

grease lubrication

possibility of grease lubrication

oil mist lubrication

oil mist lubrication for more precision

oil-air lubrication

oil-air lubrication for special use

made with precision and hand-tested

Before the Henninger angle heads leave the factory, they are thoroughly tested for speed, concentricity and heat generation to ensure perfect functioning at the end customer.

We are happy to offer youtest machinings with your workpieces. You can also rely on our contract manufacturing service.