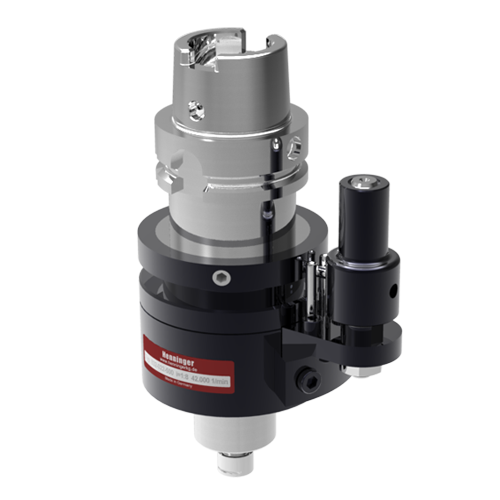

Henninger Spindle Speeders offer high speed and rigidity with maximum precision – Made in Germany.

Henninger spindle speeders increase the rpm of machine tools. Our high-precision spindle speeders are always used when the speeds of machine tools are no longer sufficient. Moreover, they are also used when the workload on the machine spindle is to be reduced.

The new generation of carbide tools require high cutting speeds, which are often no longer achieved by older machines. This is exactly the point where the Henning spindle speeders come into the picture. Whether for grinding, drilling, engraving or milling: the Henninger product line has a suitable spindle speeder for every application.

Rpm up to 50.000 min-1

Rpm are possibile up to 50.000 min-1 with Henninger spindle speeders. The spindle speeders are suitable for pre- and fine machining of workpieces. Internal coolant feeds with a pressure of up to 60 bar can also be implemented, depending on the model.

Modular shaft system

The modular shank system allows the customer to use the spindle speeders on different machines. The different shanks can be changed by the customer. The spindles can be changed manually with holding rod or torque support. In addition, there is also the possibility of an automatic tool change with a stop- and arrester attachment.

These spindle models are characterised by

- high rpm up to 50.000 min-1

- high rigidity due to special bearing

- inner coolant supply

- dry run possible

- modular cone system

suitable for:

- micro and fine drilling

- milling and grinding work

More information about the spindle speeder series 832 & 834 are here.

These spindle models are characterised by

- high torque (125 Nm)

- high power

- high rigidity

- output SK 50

- durable and sturdy construction

suitable for:

- large boring mills and machining centres

- robust machining

More information about the Henninger Spindle Speeders series 815 – 826 are here.

Use of the Henninger Spindle Speeders

- shape lines

- insertion of micro bores

- milling electrodes

- finishing

- engraving of names, logos, etc.

- grinding work with tool grinding machines

- hard machining

- deep-hole drilling

made with precision and hand-tested

All our products are designed and manufactured by us. Before the Henninger spindle speeders leave the factory, they are thoroughly tested for speed, concentricity and heat generation to ensure perfect functioning at the end customer.

The customer also receives a suitable test report with all data. With regular maintenance, our spindles are in use for more than 20 years.

We are happy to offer you test machinings with your workpieces. You can also rely on our contract manufacturing service.