Henninger Spindles, Motor Spindles, Belt Spindles, Air Speeders, Mounting Spindles & Spindle Units

The Henninger spindles are characterised by the highest precision and longevity. We offer various series and types of spindles: motor spindles, belt spindles, air speeders, mounting spindles, spindle units and all kinds of special solutions for all areas and applications. Moreover, the spindles are independent of the machine spindles due to their own drive.

Modern and precise bearing technology allows very high speeds and rigidity of the spindles. Continuous on-site development allows us to constantly implement new integrations of technologies and customer-specific special requests for all spindle models.

With over 400 different spindle types we always have a solution ready – whether electric belt or air drive.

The Henninger motor spindles offer:

- Speed up to 80.000 rpm

- Power up to 12,5 kW

- Independence from machine spindle

- Water cooling

- as attachment spindle or installation spindle

More information about the motor spindle series 940s, 960s & 965s here.

The Henninger belt spindles & spindle units are characterised by:

- high rigidity

- Longevity

- Maintenance-free

- Drive and tool holder according to customer specification

- Special solutions

More information about the 890 series belt spindles & spindle units here.

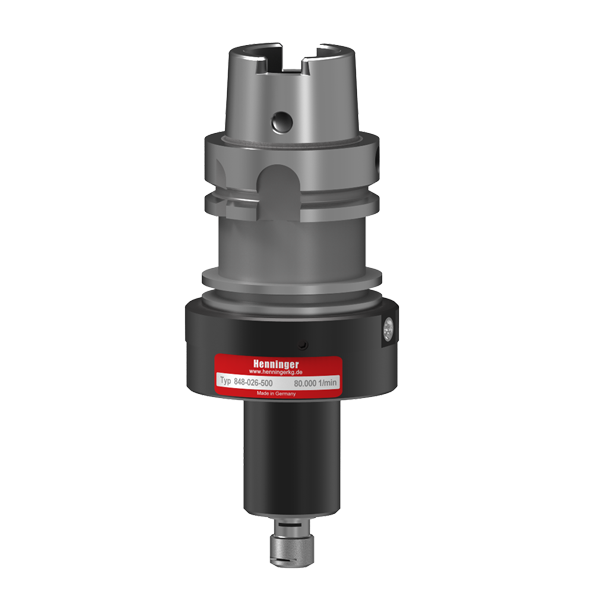

The Henninger air speeders offer:

- Speed up to 80.000 rpm

- Maintenance-free and air-operated

- Air supply laterally or centrally

- Automatic substitution possible

- High runout accuracy

- precise storage

More information about the air speeders series 848 & 852 here.

Application of our Henninger Spindles:

- shape lines

- insertion of micro bores

- milling electrodes

- finishing & deburring

- engraving of names, logos, etc.

- grinding work with tool grinding machines

- hard machining

- deep-hole drilling

We Create Precision

All our products are designed and manufactured by us. Before the Henninger spindles leave the factory, they are thoroughly tested for speed, runout and heat generation to ensure perfect functioning at the end customer.

The customer also receives a detailed test report with all data. Our spindles can be used for years with regular maintenance. In addition, the spindle wear parts can be replaced as required, resulting in an extremely sustainable and long-lasting solution when using Henninger spindles.

We are happy to offer you test machinings with your workpieces. You can also rely on our contract manufacturing service.