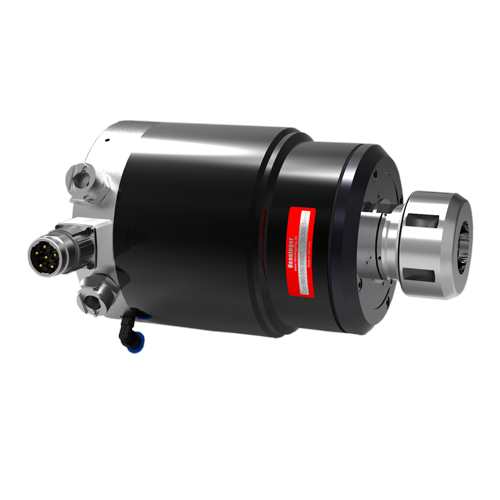

High speed up to 80.000 rpm / Power up to 12,5 kW / Made in Germany

Technical data of the Henninger Mounting Spindles of the 940 series

| type | 054 | 058 | 060 | 072 | 080 | 100 |

| speed max. min-1 | 30.000 / 60.000 | 20.000 / 30.000 | 20.000 / 30.000 | 16.000 / 30.000 | 16.000 | 12.800 |

| power max. kW | 0,25 / 0,5 | 0,5 | 0,5 | 0,3 / 1,0 | up to 4,7 | up to 11 |

| holder | collet | collet | collet / HSK / arbor | collet / HSK / arbor | collet / HSK / arbor | collet / HSK / arbor |

| dimensions | Ø 54 x 210 | Ø 58 x 147 | Ø 60 x 147 | Ø 72 x 265 | Ø 80 x 330 | Ø 100 x 320 |

| supply | plug / cable | plug / cable | plug / cable | plug / cable | plug / cable | plug / cable |

| options | A, S | A, S | A, S | A, S, D, W | A, S, D, W | A, S, D, W |

| configuration | round / square | round / square | round / square | round / square | round / square | round / square |

Options

A: AE sensor, S: standstill control, D: rotary encoders, W: water coolant

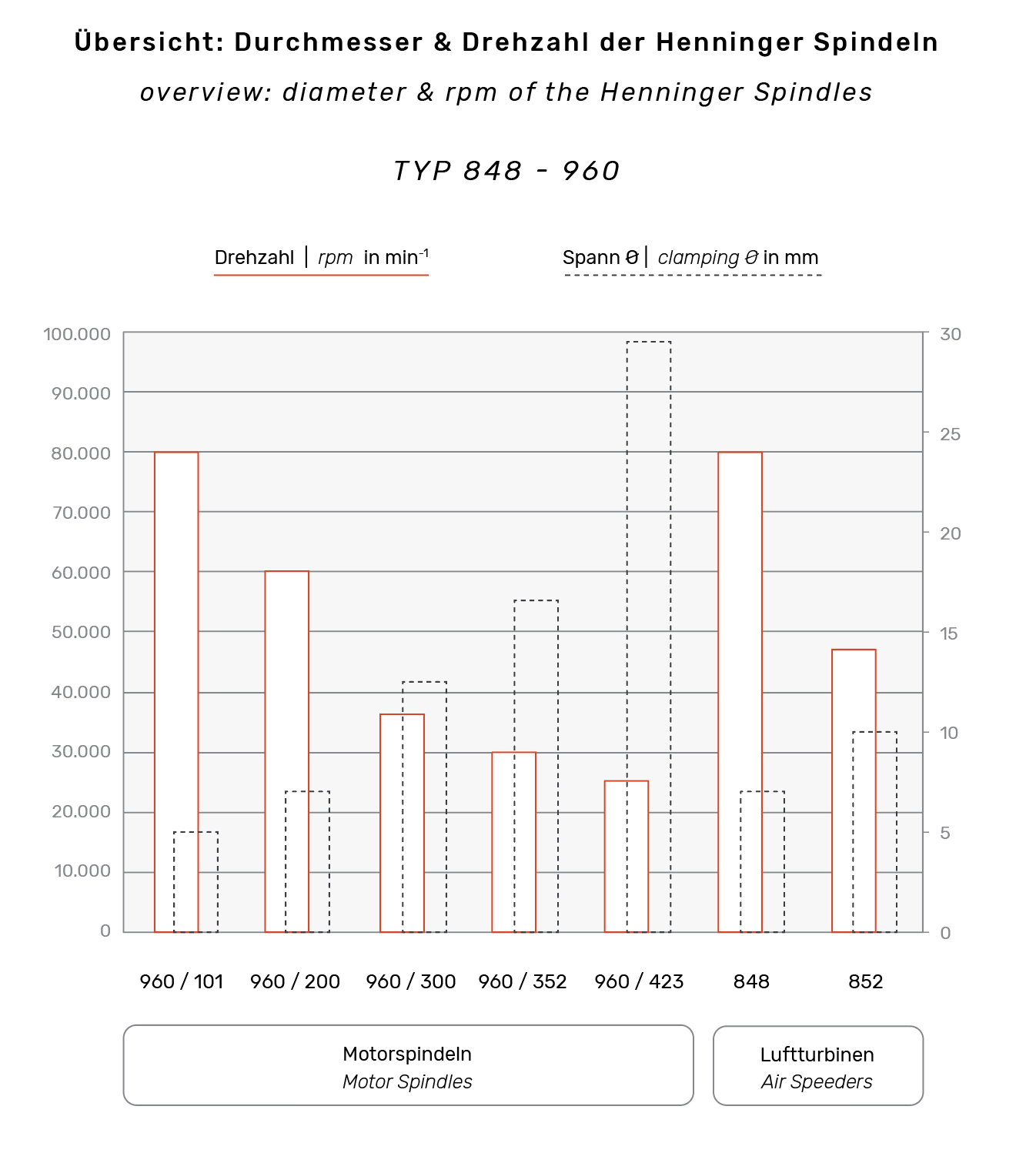

Technical data of the Henninger Motor Spindles of the 960 – 965 series

| type | 960 / 101 | 960 / 200 | 960 / 300 | 960 / 352 | 960 / 423 | 965 / 400 | 965 / 402 |

| speed max. min-1 | 80.000 | 60.000 | 36.000 | 30.000 | 25.000 | 25.000 | 25.000 |

| nominal power kW with 100% ED | 1,1 | 1,6 | 1,9 | 3,7 | 12,5 | 4,1 | 12,5 |

| max. nominal power kW with 60% ED | 1,2 | 1,8 | 2,2 | 4,5 | 15 | 4,4 | 15 |

| motor voltage V | 230 | 230 | 230 | 400 | 400 | 350 | 350 |

| clamping range Ø | Ø 1 - 5 | Ø 1 - 7 | Ø 1 - 13 | Ø 1 - 16 | Ø 2 - 30 | HSK 40 E | HSK 40 E |

| collets | DIN 6499 | DIN 6499 | DIN 6499 | DIN 6499 | DIN 6499 | DIN 69893-5 | DIN 69893-5 |

| input shank | all common shanks | all common shanks | all common shanks | all common shanks | all common shanks | all common shanks | all common shanks |

| power connection | 230 V / 50 Hz | 230 V / 50 Hz | 230 V / 50 Hz | 3 x 400 V / 50 Hz | 3 x 400 V / 50 Hz | 3 x 400 V / 50 Hz | 3 x 400 V / 50 Hz |

For which typical applications are the motor spindles & mounting spindles used by our customers?

Henninger motor spindles and mounting spindles are primarily used to increase the productivity of existing machine tools. They are used to line off moulds, mill electrodes, produce micro and fine bores, grind, tool grind and deburr. In addition, they are used in the Henninger centre grinding machines.

Do you want to rent a Henninger Motor Spindle?

Are you not sure if you want to use the spindle in the long term? We offer various test and rental offers depending on your needs.

Are you interested in more information? On site, by phone or with video call?

Contact us: