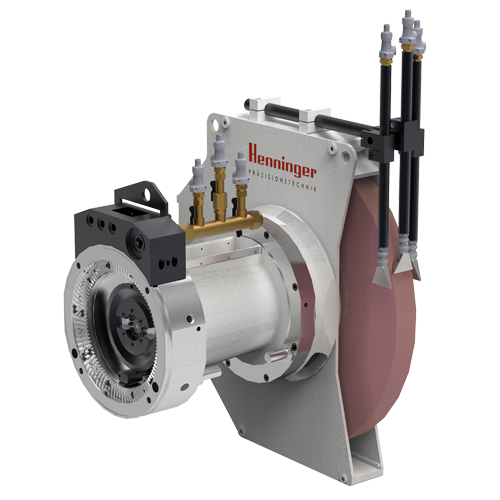

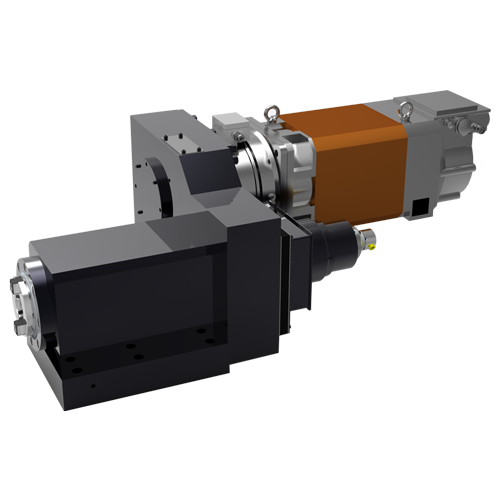

High rigidity / high precision / special solutions / Made in Germany

For which applications are the Henninger Belt driven Spindles & Spindle Units used by our customers?

The belt driven spindles and spindle units are mainly used in special machine construction, for special solutions. They are suitable for drilling, milling, deburring, spindling, grinding and even heavy machining. Furthermore Henninger Belt driven Spindles are used on test benches.

What requirements does your spindle need?

We will be happy to advise you on the design of your spindle unit. In order to advise you in the best possible way, we ideally need the following information:

- Housing shape (e.g. round, angular, flanged)

- Tool holder (e.g. grinding cone, HSK)

- automatic tightener yes / no

- Power / speed / torque

- Coolant yes / no (central or lateral)

- Drive: Interface to the machine (e.g. clutch, belt)

- Desired sensor technology (e.g. position detection, rotary encoder)

- Sealing (e.g. labyrinth, sealing air)

Contact us:

info@henningerkg.de