power up to 54 kW / high torque up to 114 Nm / designed & made in Germany

Technical data of the Henninger Spindle Speeders pf the 815 – 826 series

| Typ | 815 | 816 | 816 | 817 | 825 | 826 |

| Antrieb | modular II & alle gängigen Kegel | fest & alle gängigen Kegel | fest & alle gängigen Kegel | fest & alle gängigen Kegel | modular II & alle gängigen Kegel | fest & alle gängigen Kegel |

| Spannbereich Ø | ER 40 Ø 2-30 | ER 50 Ø 4 - 34 | SK 40 | SK 50 | ER 40 Ø 2 - 30 | ER 50 Ø 4 - 34 |

| Übersetzung | 1 : 4 | 1 : 4 | 1 : 4 | 1 : 3 | 1 : 4 | 1 : 4 |

| Druck bei innerer Kühlmittelzufuhr max. | nach Absprache | nach Absprache | nach Absprache | nach Absprache | nach Absprache | nach Absprache |

| Drehzahl min-1 / Leistung kW / 20 % ED | 10.000 7,5 | 9000 18 | 9000 18 | 4000 53 | 14.000 10,5 | 12.000 24 |

| Drehzahl min-1 / Leistung kW / 80 % ED | 8000 6 | 7000 14 | 7000 14 | 3200 40 | 10.000 7,5 | 10.000 20 |

| Drehzahl min-1 / Leistung kW / 100 % ED | 6400 4,88 | 5600 12,8 | 5600 12,8 | 2500 30 | 8000 6 | 8000 16 |

| Drehmoment max. Nm | 7,16 | 19,1 | 19,1 | 114 | 7,16 | 19,1 |

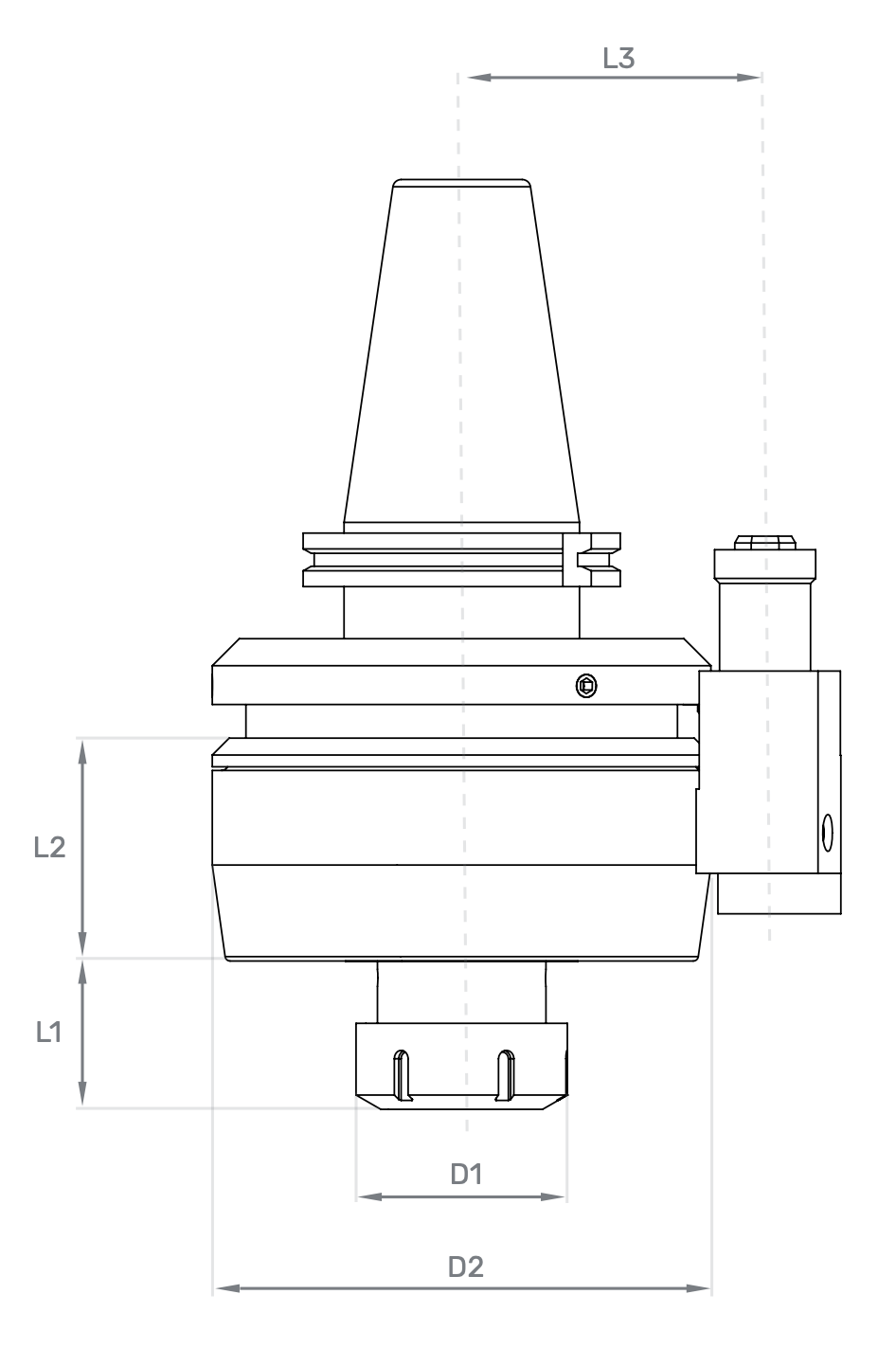

Dimensions in mm of the series 815 – 826

| Typ | 815 | 816 | 816 | 817 | 825 | 826 |

| D1 | 62,7 | 78 | 110 | 180 | 62,7 | 78 |

| D2 | 148 | 200 | 200 | 320 | 148 | 200 |

| L1 | 95,6 | 89,5 | 89,5 | 128 | 95,6 | 90 |

| L2 | 44 | 83,5 | 79,1 | 126 | 90 | 127,8 |

| L3 | nach Absprache | nach Absprache | nach Absprache | nach Absprache | nach Absprache | nach Absprache |

DF: duty factor / h

For which applications are the spindles used by our customers?

The high-speed spindles are suitable for dressing moulds with higher chip depth, for finishing, for roughing and for increasing the machine speeds when this is required for the cutting tools. They produce pockets, grooves, moulds, threads, bores and countersinks, among other things.

Do you want to rent a Henninger Spindle Speeder?

Are you not sure whether you want to use the spindle in the long term? We offer various test and rental offers depending on your needs.

Are you interested in an information session? On site, by phone or with video call?

Contact us: