Technical data of the Henninger Spindle Speeder of the 832 series

| type | 832 |

| drive | all common shanks |

| clamping range Ø | ER 11 Ø 1 - 7 |

| ratio | 1 : 7,7 |

| rpm / power kW / 20 % DF | 50.000 / 6,1 |

| rpm / power kW / 80 % DF | 42.000 / 5,1 |

| rpm / power kW / 100 % DF | 36.000 / 4,4 |

| torque max. Nm | 1,2 |

| option | inner coolant supply up to 50 bar |

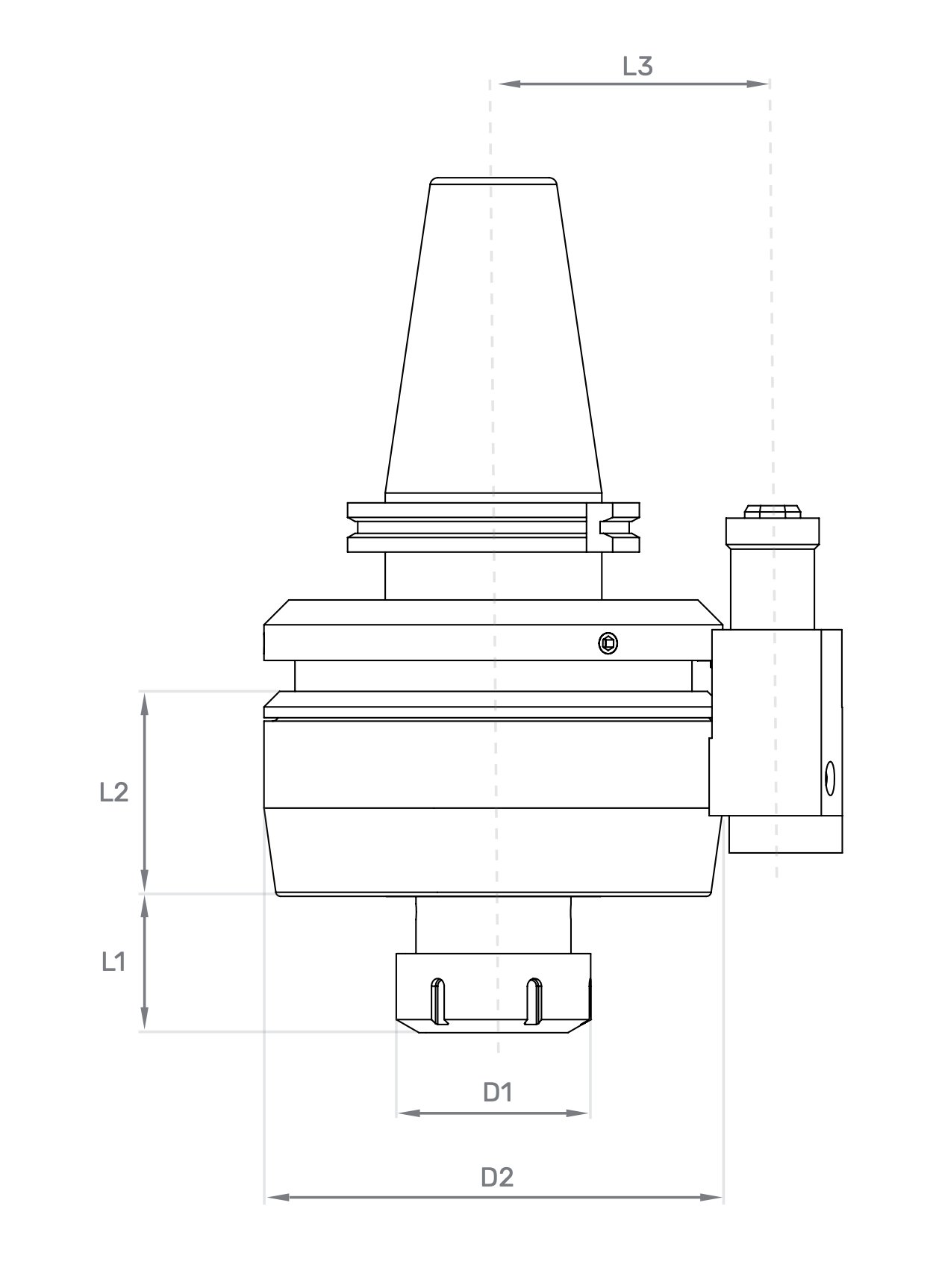

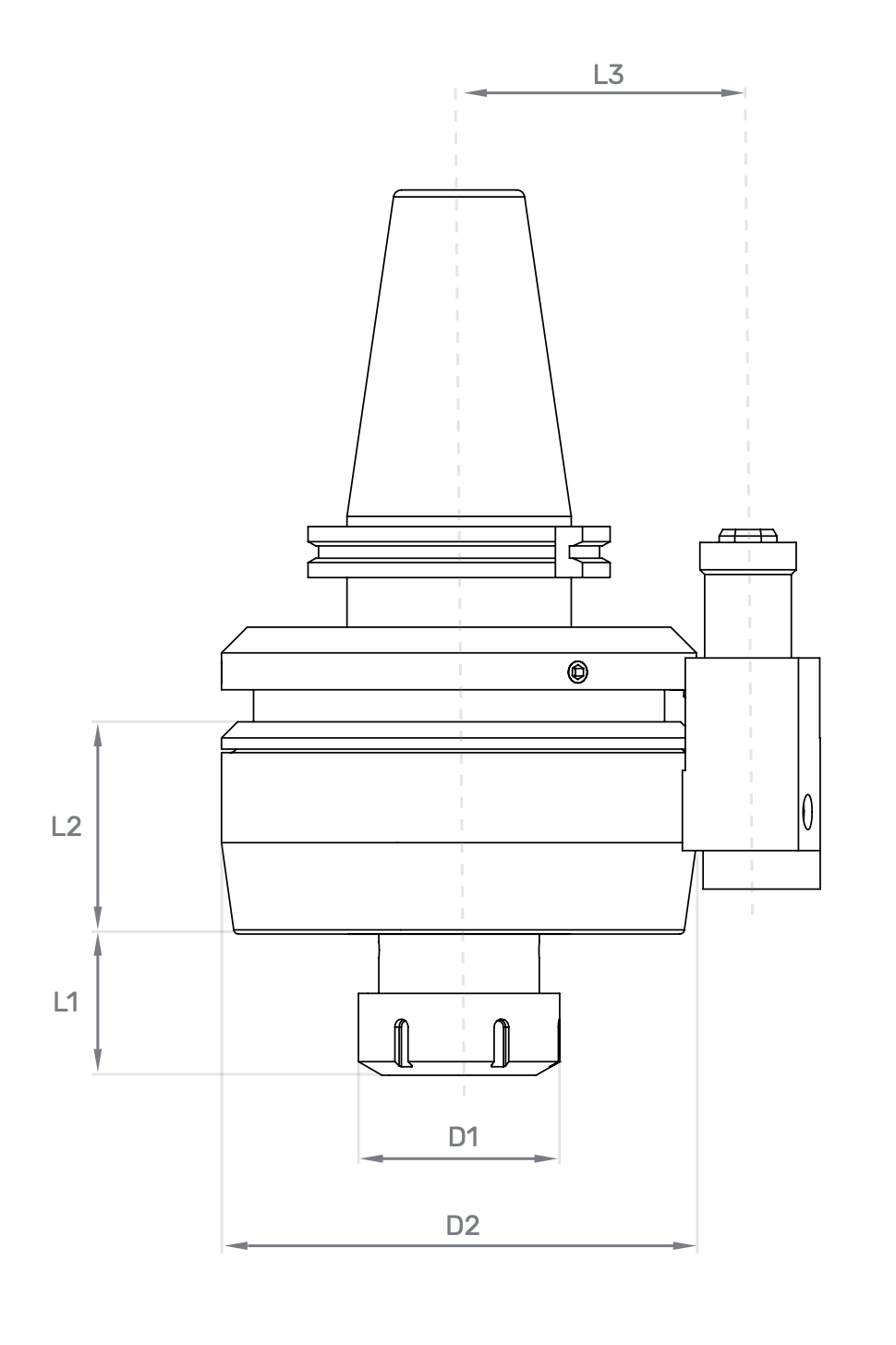

Dimensions in mm of the 832 spindle speeders

| type | 832 |

| D1 | 16 |

| D2 | 80 |

| L1 | 46,6 |

| L2 | 48,5 |

| L3 (TB / ATC) | 65 / 80 |

DF: duty factor / h

TB: torque bar

ATC: stop- & arrester attachment

Technical data of the Henninger Spindle Speeder of the 834 series

| type | ER 25 | ER 32 | HT 4 |

| drive | modular I & all common shanks | modular I & all common shanks | modular I & all common shanks |

| ratio | 1 : 5,7 | 1 : 5,7 | 1 : 5,7 |

| rpm / power kW / 20 % DF | 30.000 / 8 | 20.000 / 8 | 20.000 / 8 |

| rpm / power kW / 80 % DF | 22.500 / 8 | 15.000 / 6 | 15.000 / 6 |

| rpm / power kW / 100 % DF | 18.000 / 7,2 | 12.000 / 4,8 | 12.000 / 4,8 |

| torque max. Nm | 3,8 | 3,8 | 3,8 |

| option | inner coolant supply up to 50 bar | inner coolant supply up to 50 bar | inner coolant supply up to 50 bar |

Dimensions in mm of the 834 spindle speeders

| type | ER 25 | ER 32 | HT 4 |

| D1 | 41,7 | 49,7 | 42 |

| D2 | 125 | 125 | 125 |

| L1 | 73,6 | 76,6 | 56,3 |

| L2 | 54,2 | 54,2 | 54,2 |

| L3 (TB / ATC) | 80 / 110 | 80 / 110 | 80 / 110 |

DF: duty factor / h

TB: torque bar

ATC: stop- & arrester attachment

For which applications are Henninger Spindle Speeders used by our customers?

Typical applications include: production of electrodes, production of fine and micro drillings, line-off of moulds, finishing of workpieces, machining of hardened material, dry machining, grooving, slot drilling, deep hole drilling, grinding and deburring.

In order to be able to offer even the smallest grinding tools the necessary performance, ANCA, for example, uses our high-speed spindle 832 in its tool grinding machines. This is equipped with a coolant ring in addition to the ANCA-specific tool interface. ANCA’s full experience report can be read here.

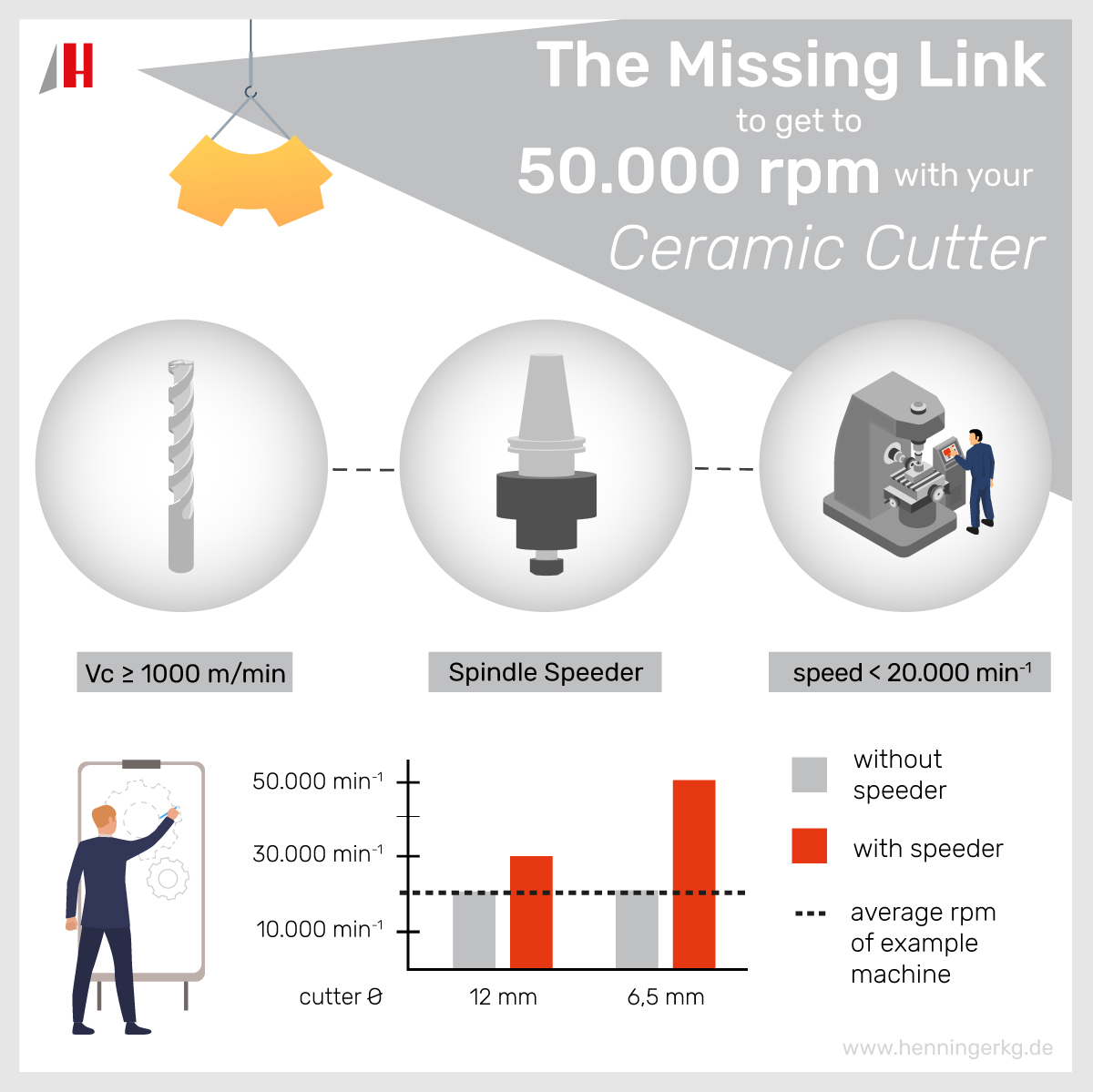

Milling with Ceramic Cutters

The Henninger spindle speeders are also ideal for ceramic milling cutters that require high speeds. This makes it possible to adapt machines with too low speeds to high-performance milling cutters.

Do you want to rent a Henninger Spindle Speeder?

Are you not sure whether you want to use the spindle in the long term? We offer various test and rental offers depending on your needs.

Are you interested in an information session? On site, by phone or with video call?

Contact us: