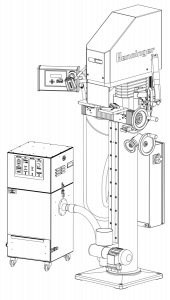

Technical data of the Henninger centre grinding machines of the ZS 1000 series

Workpiece: centre diameter

Ø 2 – 148 (188) mm

Machine: clamping diameter

10 – 250 mm / 30 – 275 mm

Workpiece: length

max. 3086 mm

Machine: speed

5.000 – 30.000 min-1 / 15.000 – 60.000 min-1

Workpiece: weight

max. 1000 kg

Customisation

with many options

What is the benefit of centre grinding?

What has the ZS 1000 series to offer?

Centre grinding with the ZS 1000 series brings high precision to the entire machining process. The perfected centre hole achieves roundness up to 1 µm and below.

Like all other Henninger products, the ZS 1000 centre grinders are characterised by a long service life. Henninger centre grinding machines, which came onto the market in 1960, are still in use today.

Our Henninger engineering team developed the ZS 1000 series especially because of requests from the aircraft industryto machine exceptionally large, heavy and unhandy workpieces with maximum precision. Moreover enquiries from large gear manufacturers also grew, such as for the production of transmission shafts for wind turbines and propellersin the shipping industry. We are constantly developing our machines and adapting them to the requests of our customers.

How do the ZS 1000 series centre grinders work?

The deformed centring holes are reworked after the hardening process. The workpiece is placed on the tailstock and clamped with the vice. The grinding head moves planetary and thus grinds the centre.

With pre-ground workpieces, the workpiece can be rotated in the vice with the stationary spindle. This makes the centre aligned with the axis of rotation.

After machining the roundness in the centre corresponds to the roundness of the workpiece. This method provides a high precision run-out.

How do the ZS 1000 series centre grinders work?

The deformed centring holes are reworked after the hardening process. The workpiece is placed on the tailstock and clamped with the vice. The grinding head moves planetary and thus grinds the centre.

With pre-ground workpieces, the workpiece can be rotated in the vice with the stationary spindle. This makes the centre aligned with the axis of rotation.

After machining the roundness in the centre corresponds to the roundness of the workpiece. This method provides a high precision run-out.

For which applications are centre grinders of the ZS 1000 series used by our customers?

Typical workpieces for the ZS 1000 series are ball screws, shafts, nozzles, machine spindles, large gears, screw drives, broaches where high accuracy is required.

For which applications are centre grinders of the ZS 1000 series used by our customers?

Typical workpieces for the ZS 1000 series are ball screws, shafts, nozzles, machine spindles, large gears, screw drives, broaches where high accuracy is required.

We offer test machinings for your workpieces

Are you not sure whether centre grinding is profitable for your workpieces? Are you curious about the extent to which the Henninger precision technology increases the quality and efficiency of your production?

Visit us on site in our test centre so that we can present our centre grinding machine series to you. We will be happy to discuss your complete range of parts and demonstrate centre grinding on your workpieces.

Alternatively, you can also send us your workpiece. We will be happy to carry out a test machining of the centre grinding on our demonstration model. You can be connected live to observethe grinding process in our test centre. Afterwards, we will send your workpiece back to you for inspection.

Would you like a Henninger ZS 1000 series centre grinding machine as a leasing option or hire purchase? We offer flexible financing options.

You are not sure whether you want to use this machine long-term? How about a 1-year leasing option or a hire purchase, for example? We offer flexible purchase options depending on your needs. No matter if it is a standard model or special design: Henninger produces all centre grinding machines in Straubenhardt near Karlsruhe in Southern Germany.

Direct purchase

We deliver the centre grinding machine to your production!

Special solutions

Do you have specific manufacturing or option requests?

Leasing

We offer various leasing offers.

Hire purchase

Our machines can also be purchased on a hire-purchase basis.