Air Speeders up to 80.000 min-1: 848 & 852

• rpm up to 80.000 min/1

• power up to 1080 W

• with lubrication

• maintenance free, air-driven

• air supply lateral or central

Angle Head 90° static: the 880s

• power up to 84 kW

• rpm up to 7.000 min/1

• torque 665 Nm

• for milling complex internal contour

• for small bore diameter

• for heavy works

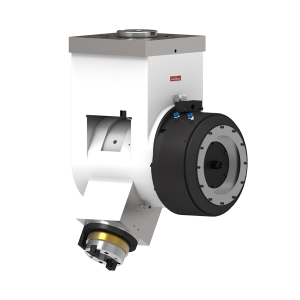

Angle Heads ± 90° adjustable: the 882s

• power up to 84 kW

• rpm up to 7.000 min/1

• torque 665 Nm

• automatic C-axis

• ± 90° continuous adjustable

• automatic tool changer

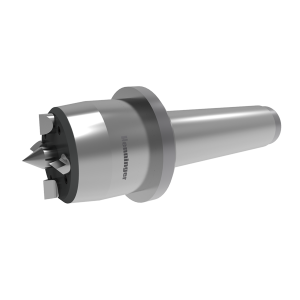

Face Driver with conversion of high run-out requests: 309 – 312

• work-piece weight up to 320 kg

• conversion of high run-out requests

• options for shaft: MT 4 / 5 / 6

Face Driver with turning range up to 105 mm: 300 – 303

• work-piece weight up to 80 kg

• turning range up to 105 mm

• conversion of high run-out requests

• shaft MT 1 / 2 / 3 / 4 / 5 / 6

HF Mounting Spindles: 940

• rpm up to 60.000 min/1

• power up to 1,3 kW

• torque 1,8 Nm

• for grinding, engraving & HSC milling machines

• section detection & more options

Live Centre 340

• work-piece up to 1,5 t

• run-out up to 1 µm

• with pressure compensation

• shaft MT 2 / 3 / 4 / 5

Live Centre 350

• run-out up to 1 µm

• with pressure compensation

• shaft MT 3 / 4 / 4S / 5 / 5S / 6 / 6S

Live Centre 360 in 60° / 75°

• run-out up to 1 µm

• with pressure compensation

• shaft MT 2 / 3 / 4 / 5 / 6

• available as 60° or 75° type

Live Centre Cones 363 & 373

• types: 60° & 75°

• run-out up to 1 µm

• with pressure compensation

• shaft MT 2 / 3 / 4 / 5 / 6

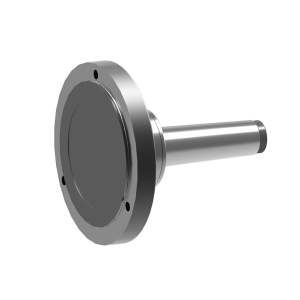

Live Chuck Flange: 380

• run-out up to 1 µm

• with pressure compensation

• with sealing ring

• hardened jaws + soft top jaws

• chuck in cast or steal

• shaft MT 2 / 3 / 4 / 4S / 5 / 5S / 6 / 6S

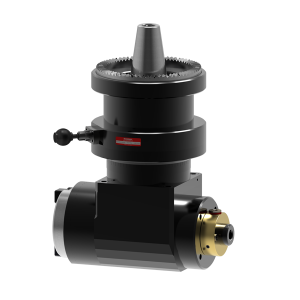

Milling Head 882 & 864

• power up to 2,1 kW

• rpm up to 15.000 min/1

• torque 3,1 Nm

• horizontal & vertical types

• for milling complex internal contour

Motor Spindles: 960 – 965

• rpm up to 80.000 min/1

• power up to 12,5 kW

• independant of machine spindle

• water-cooled

• available with modular input shank

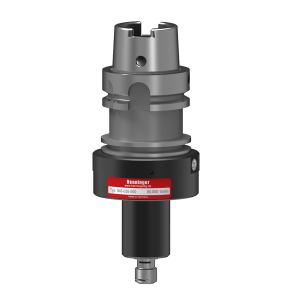

Spindle Speeder up to 50.000 min-1: 832

• the fastest of our Spindle Speeders

• rpm up to 50.000 min/1

• power up to 6,1 kW

• ratio 1 : 7,67

• inner coolant supply up to 50 bar

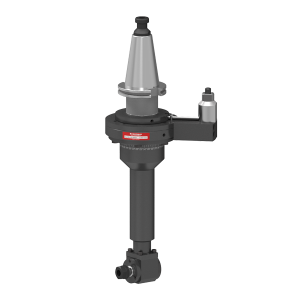

Spindle Speeders: 815 – 826

• power up to 18 kW

• rpm up to 14.000 min/1

• torque 114 Nm

• clamping range up to Ø 34 mm

Spindle Speeders: 834

• 30.000 min/1

• power up to 7,2 kW

• ratio 1 : 5,7

• high rigidity

• clamping range up to Ø 20 mm

• inner coolant supply up to 50 bar

Spindle Unit to Customer Wish

• rpm up to 40.000 min/1

• belt-driven

• main spindle for specialized machines

• tool spindle for test benches

• to customer wishes