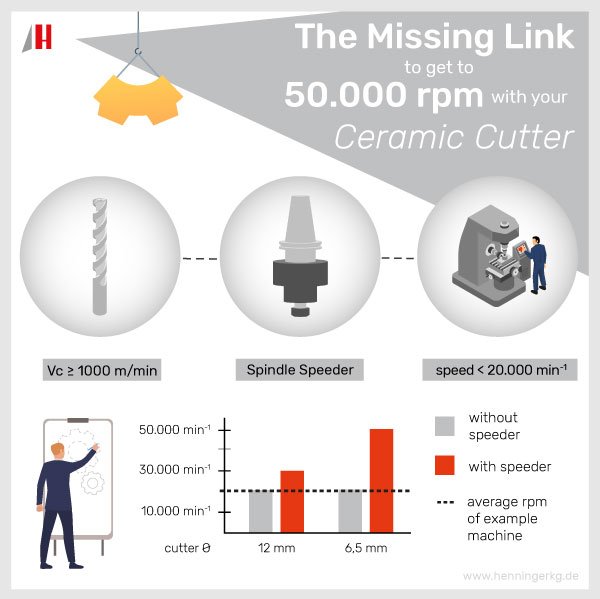

The latest all-ceramic tools promise maximum cutting speeds due to their high thermal stability. This is especially interesting for non-ferrous metals, such as AI-alloys (vc ≤ 3600 m/min) or Inconel (vc ≤ 600 m/min).

However, these promising cutting data speeds present a dilemma for the operator: he must be able to realize these with his existing machines – unless he wants to change the machine park. Conventional machining centers offer far too low speeds.

Conventional machining centers offer far too low speeds. For example, if only a maximum rpm of 12.000 min-1 is available, these high-performance tools are only interesting from a diameter of approx. 26 mm onwards. The high cutting speeds cannot be achieved with smaller diameters! If the machine is being run at maximum speed though, the endurance of the spindle decreases.

So how can one achieve higher cutting speeds with smaller tools?

One solution would be to use a spindle speeder. The speed of the main spindle is multiplied by a transmission gear. The 832 / 834 spindle speeders by Henninger offer a ratio of 1:7,6 / 1:5,6 at a maximum rpm of 50.000 min-1 / 30.000 min-1. Thus tools can be fully utilized to capacity with cutting data mentioned above. While, at the same time, the machine spindle runs at a reduced speed. This lowers the temperature rise, hence the required cooling capacity. The energy costs for the machine decrease. Moreover the service maintenance for the spindle is lessened. The spindle speeder offers a multitude of other advantages, such as the modular shank system, which enables an adaption to various machines of the customer.

Automatic changing can also be carried out with a stop and arrester attachment. Further the medium can be put with an internal coolant supply directly to the cutting edges of the tool. Thus, the spindle speeder is a tool that can bring high benefits to many machines.