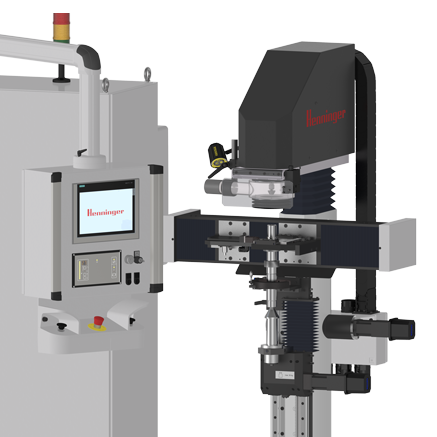

The Henninger products of the center grinding machines are characterized by highest precision, excellent concentricity, improved runout and long durability in the machining of the workpieces.

The machines are designed and manufactured in our headquarters in Straubenhardt, Germany. They are engineered for the durable application in high quality productions. Our centre grinding machines offer our customers an important way to achieve required qualitative results and increase the profitability.

We offer standard models for manual and automated situations. Our centre grinders can be adapted to the respective customer requirements with options and special solution adaptions. Our centre grinding machine series are divided according to workpiece weights, as well as horizontal and vertical alignment during machining.

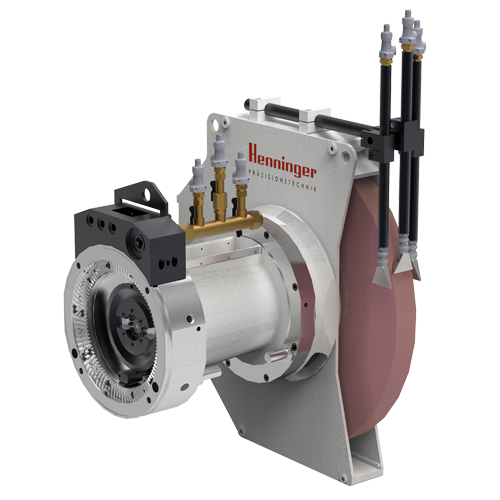

Henninger spindle speeders increase machine tool speeds up to 50,000 rpm. For this reason, the high-precision spindle speeders are used when the speeds of machine tools are no longer sufficient. In addition, they reduce the stresses on the machine spindle.

Since the new generation of carbide tools require high cutting speeds, which are often no longer achieved by older machines, high quality and precise speed boosters are needed. This is where the Henninger spindle speeders are used. Whether for grinding, drilling, engraving or milling: the Henninger company has a suitable spindle speeder for every application in its program.

The Henninger spindle series are characterised by the highest precision and longevity. We offer various series and types of spindles: motor spindles, belt spindles, air speeeders, mounting spindles, spindle units and all kinds of special solutions for all areas and applications. Moreover, the spindles are independent of the machine spindles due to their own drive.

Modern and precise bearing technology allows very high speeds and rigidity of the spindles. Continuous on-site development allows us to constantly implement new integrations of technologies and customer-specific special requests for all spindle models.

With over 400 different spindle types we always have a solution ready – whether electric belt or air drive.

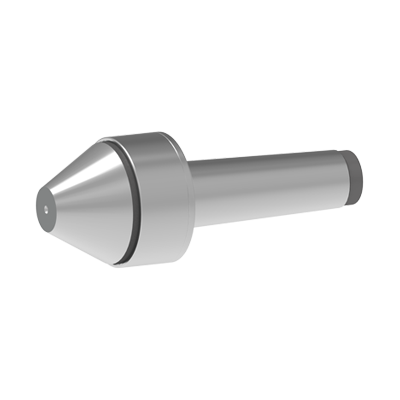

The Henninger centres series cover a very wide range of products. The 300 – 380 series, for example, consists of live centers, face drivers, centre cones and chuck flanges. High-precision centres for lathes and grinding machines allow workpiece weights of up to 30 tonnes thanks to the robust designs. Centrers from MK 1 to MK 6 as well as metric cones 80/100/120are available. Furthermore, the Henninger centres have a long service life and runout accuracies of 0.001 mm. Live chuck flanges are available for workpieces without centering holes.

An outstanding feature for Henninger is the ability to realise all types of special solutions for customers in the area of angle heads, spindle speeders, spindles, centres and centre grinding machines.

We offer you over 60 years of experience and knowledge in areas of precision and machine developments. Our engineers and designers specialise in new and innovative challenges and finding solutions to them.

Some of the special solutions are so much in demand that they become part of our standard product range. Furthermore, each standard model can also be adapted and extended according to the customer request.

Henninger has already developed more than 400 special solutions in the area of spindles, as well as more than 600 different angle head models. These are successfully in use worldwide through our international distribution network.

made with precision and manually tested

All our products are designed and manufactured by us. Before Henninger products leave the factory, they are tested to ensure proper function at the end customer. The customer also receives a suitable test report with all data.

We are happy to offer you test machinings with your workpieces. You can also rely on our contract manufacturing service.